Robotics applications in industry

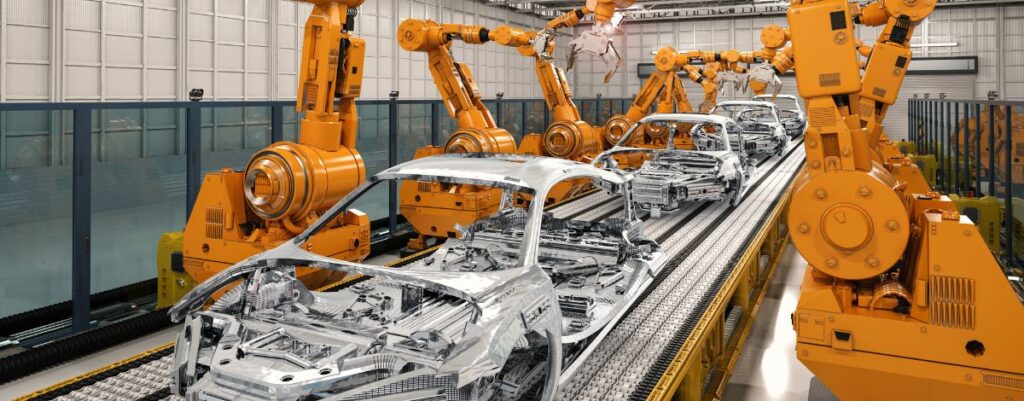

Reading time: < 3 minutesRobotics has become a fundamental element of any industrial production process. Process robotization is nowadays present in almost all industrial processes, from the food industry to the self-motive, petrochemical or metallurgical industry, warehouse management systems in logistic centres or production processes of pharmaceuticals or prosthesis for the sanitary sector.

One of the main characteristics of robotic applications in industry is their high degree of specialization in specific processes. Specific robots can be designed for almost every stage of a production line. Advances in both the mechanical and technical aspects of robots and in the technology associated with their capabilities (probes and sensors) and control (data analysis and connectivity software) make them highly skilled “workers” in many processes.

The high degree of precision made possible by the use of robotics is another important aspect to highlight, which directly affects the quality and homogeneity of the final product. Likewise, the control of the processes that enable robotic applications is a determining factor in this quality.

The use of robotics at the industrial level has also made it possible to increase the safety of procedures. This security manifests itself in two aspects. On the one hand, in the safety of the product itself (reliability and precision of the industrial process); on the other hand, robotic applications in industry also mean an increase in worker safety.

Robotic applications have meant a radical change in all the industrial processes in which they have been implemented.

Among the industries in which robotics marks a before and an after are the movement and management of goods at all levels: from inventory management in a factory warehouse, to the handling of a large number of goods in logistics and distribution centres, to baggage management in airports or the handling, control and distribution of containers in large industrial ports.

At the level of warehouse management and goods movement, the use of robots and automated systems (equipped with the latest technologies in geolocation, management software and process optimization systems) has considerably increased the capacity and efficiency of these distribution centers. But it is important to stress that all this technology will not be really effective if the structures and associated mechanical transport systems (conveyor belts, roller conveyors, etc.) do not have the highest standards of reliability and quality.