Systems for positioning conveyors

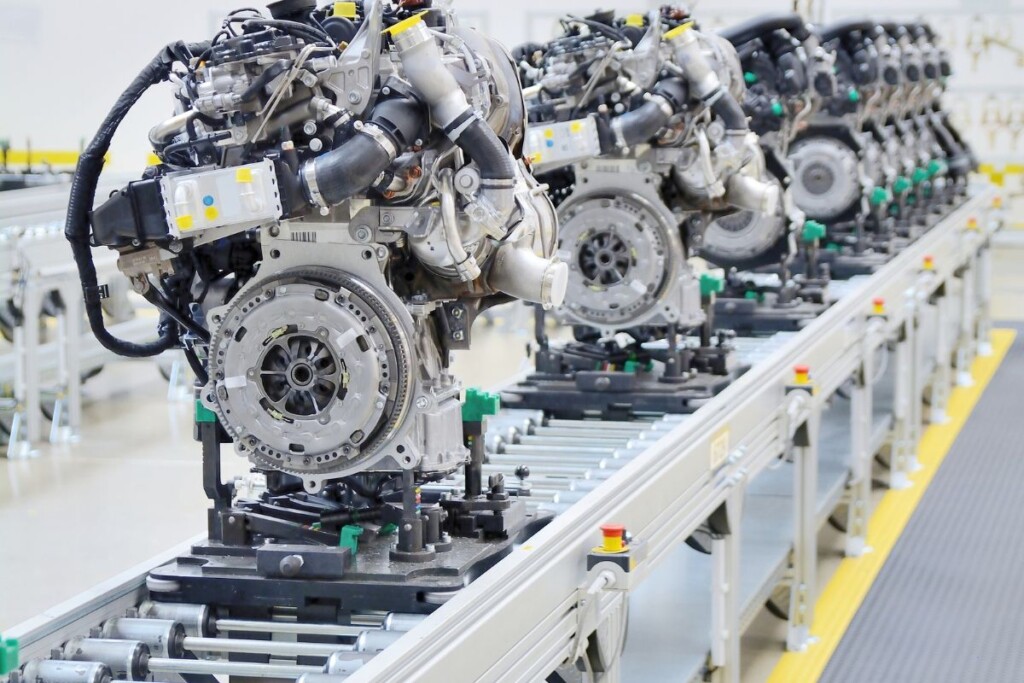

Reading time: < 4 minutesIn the modern era of automation and efficiency, systems for positioning conveyors play a crucial role in optimizing industrial processes. These systems are designed to ensure a continuous flow of materials and products along production lines, enabling smooth operations and improving overall productivity within companies.

In this post, we will explore the different types of systems for positioning conveyors and how they can enhance efficiency and profitability across various industries.

Rail systems

One of the most common systems for positioning conveyors is the rail system. These systems use a series of strategically placed rails to guide conveyors and ensure their precise positioning. The key advantage of rail systems is their ability to move with great speed and accuracy, allowing a constant flow of products along the production line.

By utilizing advanced technology such as sensors and controllers, rail systems can quickly adapt to the changing needs of production. These systems can also integrate with other equipment and machinery, further improving efficiency and reducing downtime. With their precise handling and positioning capabilities, rail systems have become a popular choice in sectors such as automotive, electronics, and the food industry..

Conveyor belt systems

Another widely used system for positioning conveyors in industry is the conveyor belt system. These systems use a continuous belt that transports materials or products along the production line. The main advantage of conveyor belts is their flexibility and versatility, as they can be adapted to different shapes, sizes, and weights of loads.

Conveyor belt systems are especially useful when handling large or bulky products. Additionally, these systems can be configured to transport materials at angles or curves, allowing for more efficient plant design.

The automation of conveyor belt systems through advanced control and tracking technology further enhances their efficiency and accuracy in positioning conveyors. These systems are widely used in sectors such as logistics, packaging, and distribution.

Carousel systems

Carousel systems are a popular choice for positioning conveyors in automated storage and retrieval environments. These systems consist of a series of rotating storage stations that store and transport products to pick-up or processing points. The circular design of the carousels allows for optimal space usage and efficient product handling.

Carousel systems offer rapid product retrieval and a significant reduction in waiting times, improving efficiency and profitability in operations. Furthermore, the automation of these systems through control and tracking technology ensures reliable and precise positioning of conveyors. Carousel systems are commonly found in automated warehouses, distribution centers, and sectors such as e-commerce.

Robotic systems

With the advancement of robotics, robotic systems for positioning conveyors have gained significant importance in industry. These systems use programmable robotic arms equipped with advanced sensors to handle and position conveyors precisely and efficiently. The main advantage of robotic systems is their flexibility and adaptability, as they can be programmed to perform a wide range of tasks and adjust to different types of products and positioning requirements.

The ability of robotic systems to interact with other equipment and machinery, as well as their capacity to work in collaborative environments with humans, makes them a versatile solution for modern industry. Additionally, these systems can be integrated with vision systems and machine learning to further improve their accuracy and efficiency in conveyor positioning. Robotic systems are used in industries such as automotive, electronics, logistics, and general production.

Sorting or classification systems

Sorting or classification systems are essential for ensuring efficient organization and optimized product flow in industry. These systems use automated sorting techniques, such as sensors, barcode readers, and vision technology, to identify and classify products quickly and accurately.

Once the products are classified, sorting systems direct each product to its designated destination, whether through conveyors, belts, or other means of transportation. These systems ensure that products are sent to the appropriate locations efficiently, reducing handling time and minimizing errors. Sorting or classification systems are used across various sectors, including logistics, retail, and the food industry.

By investing in appropriate conveyor positioning systems, companies can improve the efficiency of their processes, reduce downtime, and increase profitability. With advanced and ever-evolving technology, these systems continue to revolutionize the way industrial operations are carried out.