Industrial Automation, what is it and how does it works?

Reading time: < 2 minutesIndustrial processes have undergone a significant development in automation in recent decades. Its progress has become a very important key in this sector, because its use allows full optimization of resources, increased production and higher product quality. For all this to be possible, these automation systems must be precise and detailed, without improvisations and, measured almost millimeter.

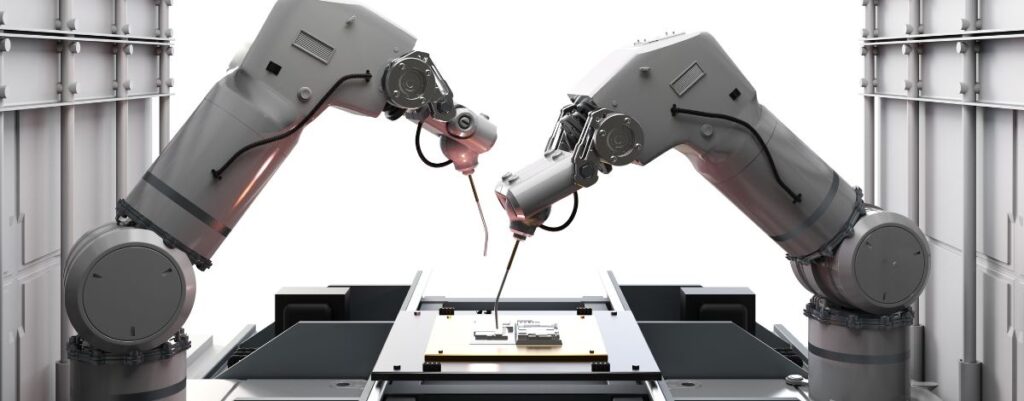

The implementation of these systems consists of the application of a whole series of technologies aimed at the control and monitoring of an industrial process, such as machines or devices that perform repetitive tasks, so that their operation is automatic and human intervention is practically null. In this way, it is possible to manufacture the largest number of final units in the shortest possible time, making it possible to reduce costs without affecting quality.

Digging deeper into these systems, we can deduce that on the one hand, automation intended to help measure matter in different states; solids, gases and liquids (volume, weight and precision). On the other hand, it is based on motors, which can be pneumatic, by servos and on behalf of other systems that involve movements or movements of a product or object.

The communication elements that interconnect the various parts of the automated process are another aspect, as are the controllers that allow automation to run in a logical and programmed way. In other words, the main objectives of this automation are defined as optimizing product quality, reducing manufacturing effort and time, improving productivity and reducing costs, minimizing occupational risks and preventing machinery breakdowns

With industrial automation, we are going to reduce repair costs and breakdown times due to breakdowns, which will translate into greater system efficiency and better economic performance. A great step in this system has come from the hand of the internet, which allows a better interconnection between systems, so that processes are digitized and controlled by computer through the use of artificial intelligence, the great ally of this revolution.