Use of sensors in conveyors to improve productivity

Reading time: < 4 minutesIn the world of industrial automation, conveyors play a key role in production efficiency. The incorporation of sensors into these systems has revolutionized how operations are managed, optimizing workflow and enhancing productivity.

In this blog, we will explore how the use of sensors in conveyors can make a significant difference in industrial operations, improving productivity.

What are sensors and how do they work in conveyor systems?

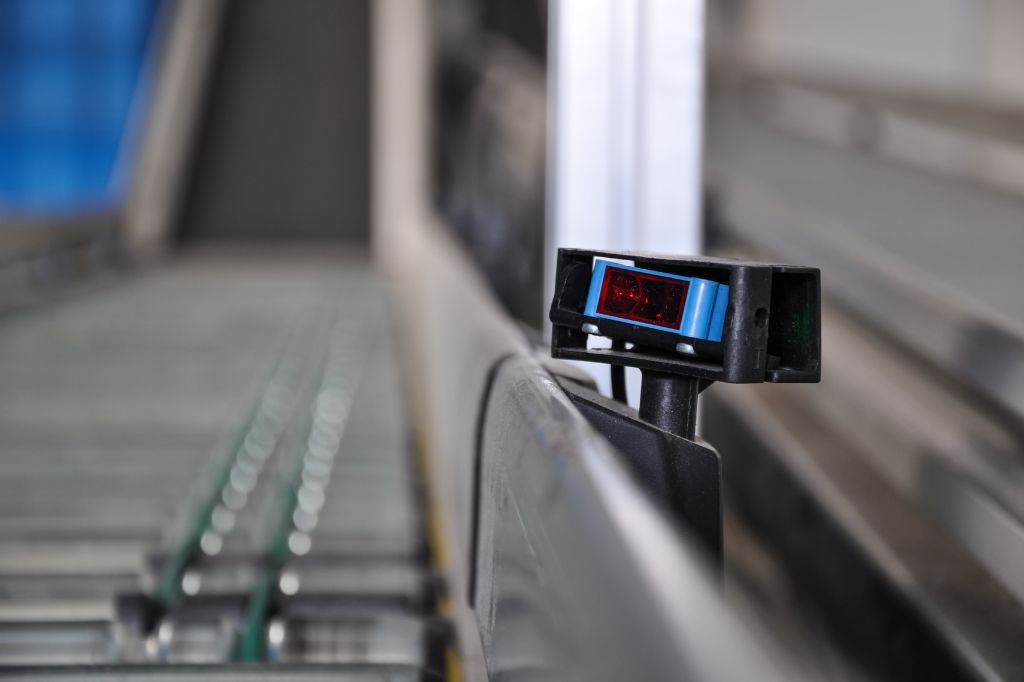

Sensors are devices that detect changes in the environment and respond to them by sending electrical signals. In conveyor systems, these devices are used to monitor various aspects such as speed, position, and temperature.

These sensors are typically located at the beginning, middle, or end of the conveyor belts, depending on the production process. The data collected by the devices is sent to a central control system, which makes real-time decisions to adjust operations and optimize performance.

There are different types of sensors used in conveyors, each with a specific function:

- Proximity: Detect the presence or absence of an object in a specific position. They are important for preventing collisions and keeping the flow of products moving. For example, in a car packaging line, proximity sensors can stop the belt if a component is not properly placed.

- Speed: Measure the speed at which products move on the conveyor. These devices help maintain a constant speed and prevent bottlenecks. In the bottling industry, speed sensors ensure that bottles are transported at the same speed as the filling machines, preventing spills.

- Weight: Weigh products in real-time, ensuring that conveyors are not overloaded, thus preventing damage to the system. In a food packaging company, these sensors play a key role in ensuring that each package contains the correct amount of product.

- Temperature: Monitor the temperature of products, especially useful in conveyor belts for food or chemicals, where temperature is a critical factor. In a frozen food processing plant, temperature sensors can ensure that frozen products stay at the correct temperature during transport.

Key benefits of using sensors in conveyors

The use of sensors in conveyor belts offers numerous benefits that contribute to improved productivity and reduced operational costs. Some of the most notable benefits include:

- Improved Operational Efficiency: By monitoring the product flow in real-time, sensors help detect downtime and prevent disruptions.

- Reduced Human Errors: Sensors automate many tasks that would otherwise require human oversight, reducing the likelihood of human error.

- Increased Safety: By detecting dangerous or unusual situations, such as overloads and extreme temperatures, sensors can trigger alarms or stop the process automatically to prevent accidents.

- Better Inventory Management: Sensors can integrate with inventory management systems to track the real-time location and quantity of products-