Types of conveyors for industry

Reading time: < 3 minutesThere are different conveyor systems for industry. The use of one or the other will depend on the type of materials being moved, the need for handling stations, packing

stations with operators, etc. and the physical characteristics of the manufacture or

warehouse in which its installation is required.

The productivity and safety of many industrial processes depend to a great extent on the efficiency and proper functioning of these transport systems ; being able to increase the efficiency of almost all the processes in which they intervene (packaging, picking , selection and distribution, conveyor systems for unloading; etc.)

To select one type of conveyor or another we have to consider several fundamental

aspects: the industrial sector and the type of products or materials to be transported

(weight, size, fragility, temperature, etc.); the physical space where the conveyor is to be installed; the type of circuit that should do; transport speed; the need for handling points; etc.

We also have to take into account that our industrial activity or our warehouse may

require different types of conveyors within the production chain.

The main conveyors used at an industrial level are the following:

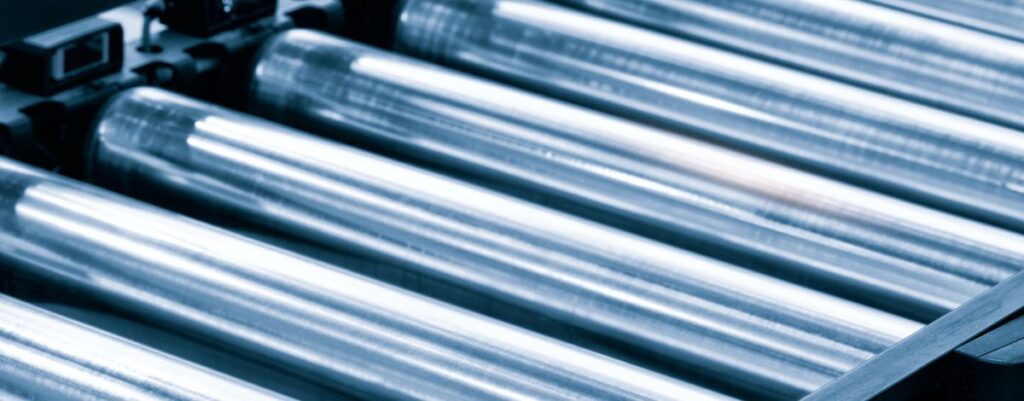

Roller conveyors

The conveyor rollers are used in a wide variety of industries. Thanks to the different options of manufacture, the roller conveyors have one great versatility and adaptability to many different types of load and materials, can be roller conveyors

movement gravity or motorized. In addition, it allows a high degree of automation

and control system. Currently they play a key role in the warehouses of a large number of industries and logistics centers due to the great increase in online sales and internet commerce.

Belt conveyors

Belt conveyors are another system widely used in a large number of industries,

warehouses and logistics centers, alone or in combination with industrial roller

conveyors. The main difference with the previous ones is that it provides a continuous surface for displacement. The belt manufacturing options as well as the

different load capacity allow a great versatility of uses, from delicate materials such as those in the fruit and vegetable sector to cutting and heavy materials such as those handled such as in scrap yards, mining industries, etc.

Chain conveyors

Chain conveyors are mainly used for heavy loads or those that are transported at high temperatures. Its robustness allows them to transport pallets, heavy boxes, containers, etc. There are widely used for example in the automotive industry.

Stacker cranes

It is a system for transporting loads at height for stocking at different levels of

stables. It allows the movement of goods vertically, although we also have double

vector movement systems (horizontally and vertically). Its use was the next

technological step to the forklift. The stacker cranes are used in logistics centers and

warehouses since it allows a great use of storage spaces in height. it may require being manipulated by an operator or working autonomously (robots).

The industrial conveyors are in many sectors the base of the production

chain. The installation of an industrial conveyor may require a significant initial investment, for this the design and manufacture of the conveyors that we do, it must always be carried out by solvent companies with experience in the industrial conveyor sector.