What is RPA? Robotic Process Automation in logistics

Reading time: < 3 minutesRobotic process automation or RPA (robotic process automation) is the business process automation involving routine and repetitive manual tasks by robots. For this, software robots are used that will interact with the software in the same way as human personnel would with greater efficiency and for 24 hours if necessary. This achieves a reduction in costs, minimization of errors and reduction in the time of personnel employed in routine tasks. These human resources can be used in a more valuable and productive way in other tasks that do require human intervention because they are still outside the automation capacity.

With RPA software, it is not physical robots that perform repetitive tasks related to physical actions, but rather software robots that perform software tasks of varying degrees of complexity; from filling in forms or issuing invoices to contact systems with customers or suppliers. Robots can perform any activity that was previously performed by humans, transfer files, copy and paste data between different software, modify files, fill in and use data in different applications, extract information from documents (spreadsheets, word processors, PDF, search engines …) and export them to other applications, sending emails, etc. at the same time, RPA allows to improve processes by analyzing the data generated (error analysis, process efficiency control, etc.).

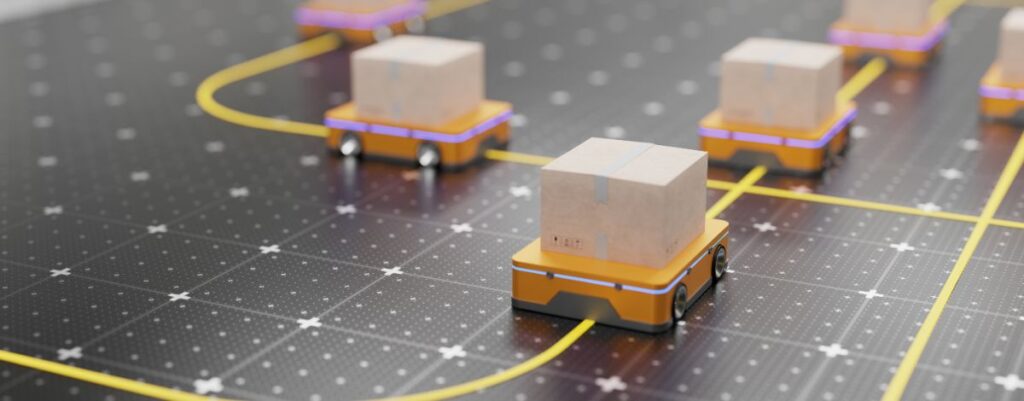

The robotic process automation is easily integrated into any workflow automated in a company. For example, such as the one that is carried out physically with automation and robots in the movement and transport of products and goods in logistics centers.

The profitability of the RPA is ensured in those processes that require the handling of a large number of data and that follow repetitive procedures such as the case of logistics companies: order entry, exit, preparation, stock control, articles, suppliers, invoices, etc.

In addition, if properly planned and designed, RPAs are scalable processes that facilitate business growth.

The implementation of RPA systems

RPA robots follow and use work rules. For the successful implementation of an RPA system it is necessary to consider the following points:

- Prepare the company for the shift towards automation. RPAs should be part of an overall automated operation and management objective. It must be integrated into other automation systems in the company.

- Analyze the process or processes to be automated, its effectiveness. Know that all the procedures that are performed are necessary and have a reason. Know the benefits that this technology will bring to these processes.

- Choose the appropriate platform for the needs of the production system.

- Planning, design and costs. Know that the implementation of an RPA system requires a minimum time and adaptation process with its associated costs. Therefore, it is essential to have the appropriate technical advice for its implementation.